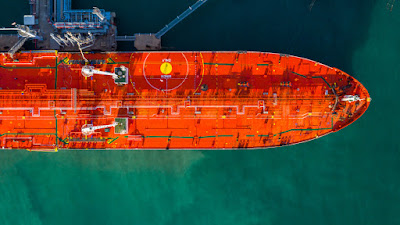

Simplify Port Operations with Automation Processing

In spite of the fact that ports have embraced automation processing at port operations more gradually than equivalent areas, eminently mining and warehousing, the movement is currently beginning to quicken. Robotized ports are more secure than regular ones. The quantity of human-related interruptions falls, and execution turns out to be more unsurprising. However the direct front capital uses are very high, and the operational difficulties—a deficiency of abilities, helpless information, siloed activities, and trouble dealing with special cases—are extremely huge.

Challenges with Port Operations in Automation:

Despite the publicity, not all – or maybe even

any - mechanized terminals are at present conveying as per details or desires.

Dependability is a key factor and providers need to raise their game to satisfy

the new need. Terminals additionally need to plunge profoundly into support.

Not exclusively does the robotized unit have greater hardware that can come up

short -, for example, scanners, lasers, etc. - even a 'back of the envelope'

figuring appears a major issue.

Testing of Solutions at Port Operations:

One test is that of expanded boat sizes-super ships as they are called. Port framework is being compelled to create and improve to fulfill these new needs needed for accepting super ships. Mechanization would help dodge port blockage, decline port stockpiling charges, and decrease demurrage and detainment.

|

| Simplify Port Operations |

Regions of Automation Processing at Ports:

By and large, there are three head regions of

port robotization – the entryways, the Ship-to-Shore cranes, and the stacks.

Automation at port doors:

Port doors are a critical checkpoint for

distinguishing and recording each element entering or leaving the port. For

ships, it likewise incorporates extra security checks, confirmation, customs,

migration, and isolation. These are critical errands, important to ensure the

uprightness of the port and require the usage of severe safety efforts.

As the volume of compartment traffic through the

port builds, these cycles devour a ton of additional time, by virtue of manual

restrictions. Computerizing fundamental cycles, for example, passage/leave

logs, confirmation, and docking installments should be possible with the

assistance of significant innovation. This makes the whole cycle stream a lot

of smoother and efficient.

|

| Ship to-shore Cranes |

Ship to-shore cranes:

Coordination’s the board with IoT comes

vigorously during the boat to shore conveyance of payload shipped by ships. The

utilization of both, monitored and automated cranes for emptying is presently

common. Over the globe, there are just 30 terminals that can be considered

completely robotized, with regards to compartment transportation.

Mechanized cranes are utilized to convey the

holders from the boats to the port utilizing automated flat transportation or

automated yard cranes. These are later ordered by the sort of payload and

stacked as needed in the stock. These holders taking care of frameworks are

steady, unsurprising, and exceptionally proficient. As the cranes are

constrained by a PC, the arranging and execution measure turns out to be very

smooth, accomplishing the necessary results at all conceivable times.